产品展馆PRODUCT CENTER

联系我们CONTACT US

Add: #850 Yatai Road, Xiaoshan District, Hangzhou, China

Tel:+86-0575-87562186

+86 13906740412

Fax:+86-0575-87562186

E-mail:xsfld@vip.126.com

Web.:www.tps2008.com

| Model No.:TPS-S8900 |

| Category:TPS Series Channel Letter Bending Machines |

| Date:12/18/2014 |

| Clicks:1236 |

Content:

TPS-S8900 automatic channel letter bending machine is conducted a comprehensive upgrade based on our TPS-S8700 precision automatic letter bending machine. It is substantially improvement in the bending strength and processing height; This new machine has larger torque and higher precision Its max. processing height gets 180mm and max. stainless steel material thickness is 1.0mm. It is the high-end bending equipment for the first selection especially suitable for the high letter(usually found in square and plaza), LED letters, stainless steel letters, punching letters, resin letters, giant glowing letters, etc.

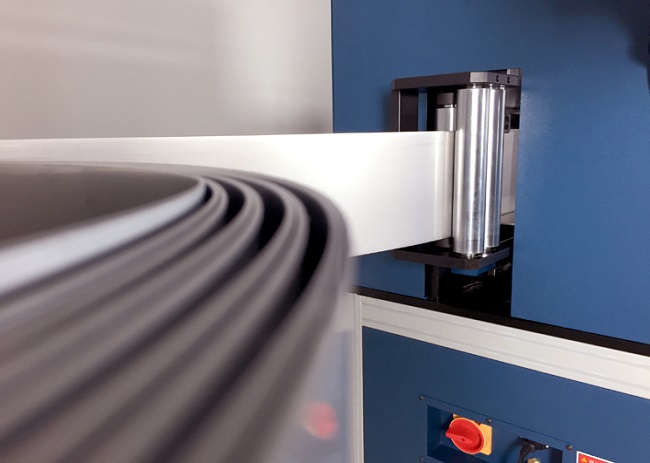

Reel type feeding

The front roller flattening mechanism, it can flatten materials effectively in advance, to avoid jam due to uneven materials.

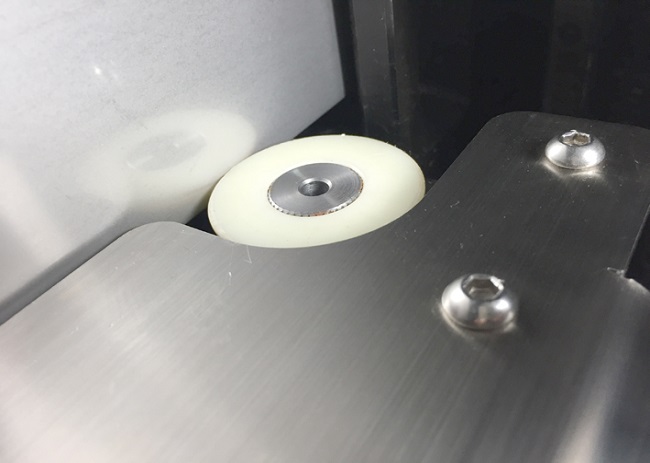

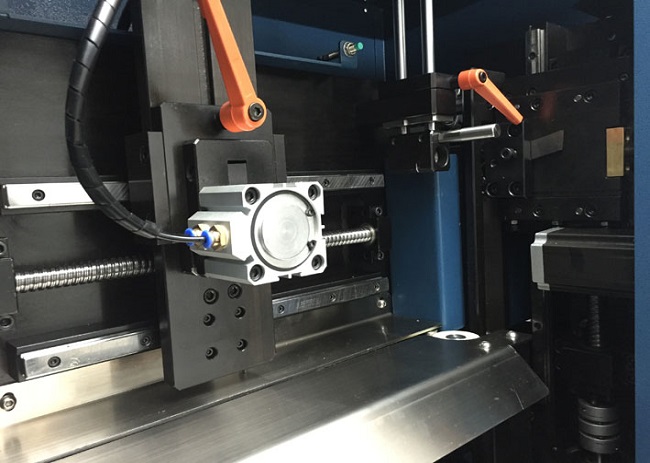

Alternating clamping feeding mechanism

Slide rail type pressure device and the plate guide chute, to avoid the phenomenon of arch material and ensure smooth feeding process. Alternating clamping feeding mechanism includes servo motor controlling and double screw nut driver, with large torque, which has high precision and high speed transmission performance to ensure actual feeding accuracy to ±0.1mm and to eliminate physical skid phenomenon due to the roller pressure feeding.

Closed loop control system

All TPS bending machines have material tracking system which can real timely monitor any material stretching and slipping during bending. With this closed-loop control of material length, precise matching bended letter with panel face letter can be garanteed.

V-shaped slotting mode

In the process of metal letter surrounding edge processing, slot mechanism is very important. Its work frequency is very high, the load is large. In order to meet the bulk processing, the mechanism should be strong and mechanical should be durable, our machine uses vertical plane v-shaped slot. Mature technology, stable performance and reliable, suitable for stainless steel, galvanized sheet, aluminum and other metal materials for V slotting.

1、 Intelligent control slot depth, free setting total slot depth, single slot depth and slot numbers.

2、 Servo motor control, high precision nut driver, with the advantages of slot speed, high accuracy and constant torque.

3、 V slotting surface is smooth, without any burr. Depth is consistent. The R Angle is not obvious when angle bending. Ensuring letters with clear and beautiful outline.

4、 Uses high strength, dovetail shape blade guide rail mechanism, its impact resistant ability compared with the straight line guide rail mechanism ascending more than 10 times.

5 、The blade material is imported high speed steel. High hardness, high temperature resistant, don't need to make real-time cooling tool during the operation. The blade is with cutting points at both ends. And it can be repeated grinding to make higher efficiency and lower cost.

6、 Slotting with low noise, no Mars, no soot. And the machine is with metal mess catcher cup. Suitable for dust-free workshop.

7 、Plating surface after slotting is colorless. It can meet the characteristics of no fine polishing when slotting mirrored, rose mirrored, plating titanium surface and other non-ferrous materials, to ensure the fine finished products.

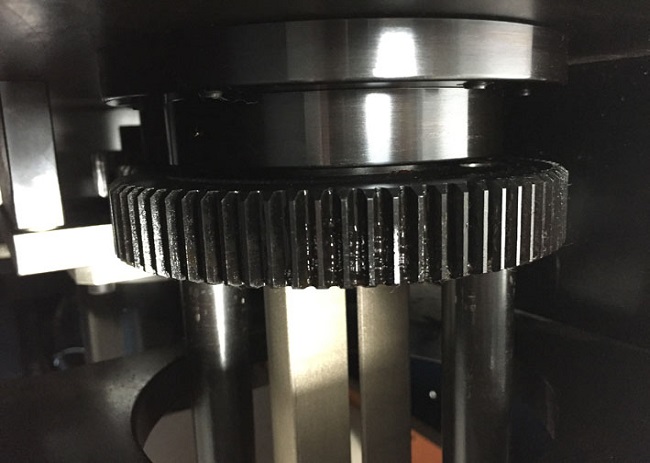

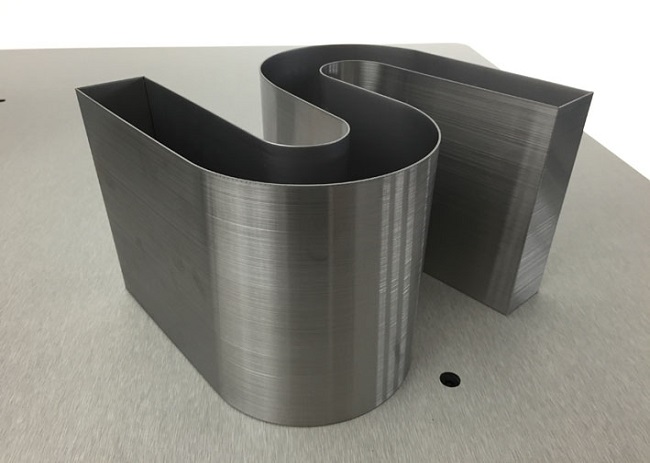

Telescoping double bending bars mechanism

The core of the bending machine is arc shape effect. TPS-S8900 automatic channel letter bending machine uses servo control, high rigid gear transmission, telescoping double bending bars, bending mold quick change system with large bending torque, small interference area, no scratch surface, material thickness is adaptable, suitable for high precision, high strength of industrial signs processing.

The equipment details

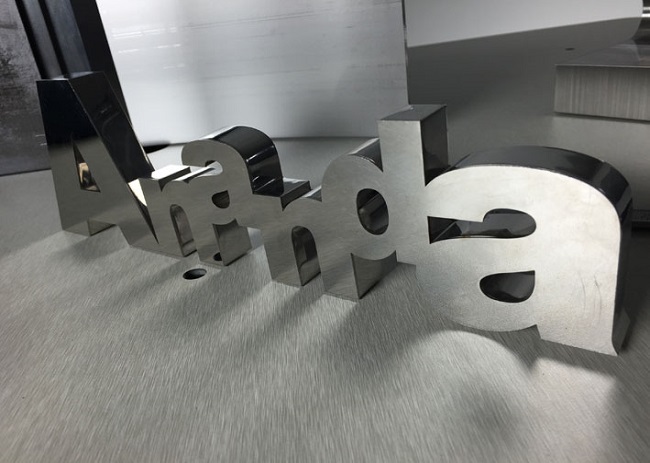

Letter samples bended by the bending machine TPS-S8900

Technical Specification

| Power supply | AC200V |

| Power | 2.5kw |

| Compressed Air | 0.4—0.8MPa |

| Axis numbers | 4pcs |

| Min. Curving radius | R7mm |

| Min. Distance between interal and external angles | 4.5mm |

| Start to Bend Distance | 3mm |

| Applied Materials | Stainless steel , galvanizer and aluminum flat surface plate and reel materials |

| Material Thickness | 0.6—1.0mm for stainless steel, 0.6-2.0mm for aluminum |

| Processing Height | 20—180mm |

| Material Feeding Method | Alternating double screw rails feeding |

| Servo Motor Quantities | 3pcs |

| Step Motor Quantities | 1pc |

| Machine N.W.: | 600kg |