产品展馆PRODUCT CENTER

联系我们CONTACT US

S1800全自动剪齿 弯字机 简介:

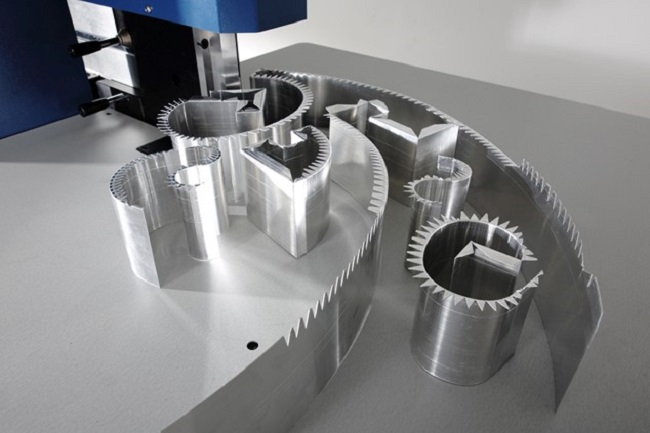

TPS-S1800全自动弯字机基于S8900机型的平台上增加了一组剪齿折边功能模块,采用多刀杆折弯系统及模具快换系统对材料进行精密折弯,不仅具备S8900全自动弯字机的所有功能外,同时还具有平面铝卷自动剪齿与折边功能,是高档广场景观字、不锈钢字、冲孔字、树脂字、巨型发光字围边的高端设备。

视频介绍

S1800全自动剪齿弯字机优势

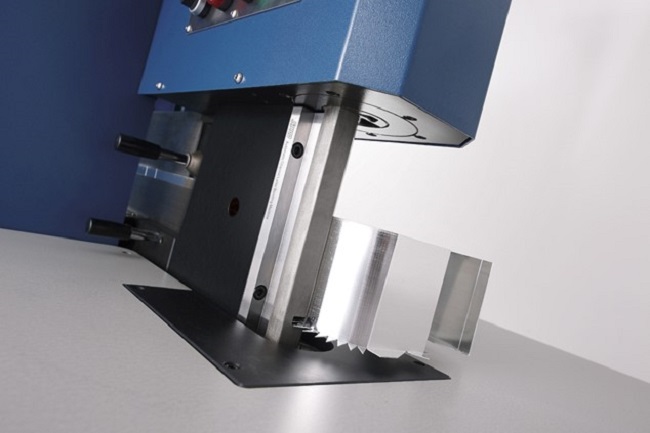

折弯模具快换系统

为了适应不同材料的高品质折弯要求,TPS公司研发得折弯模具快换系统,可在平板材料与铝型材材料之间自主快速更换,彻底解决多类型材料不能在同一台设备上无损精准折弯的行业难题。

多刀杆折弯系统

在伸缩式双弯刀折弯系统基础上,增加一组专业折铝型材的折弯刀杆,可实现平板材料及铝型材材料加工过程中的自由切换,大幅提高折弯成型度。

盘式送料

前置辊式矫平机构、针对材料材料弯曲变形进行有效的预先矫平,消除应材料不平整而引起的卡料

送料机构

交替式送料机构采用伺服控制、双丝杠螺母驱动,具有大力距、高精度、高速度传动性能,确保实际送料精度达到0.1mm,杜绝了滚压式送料的物理打滑现象及压力过大引起的压痕现象。

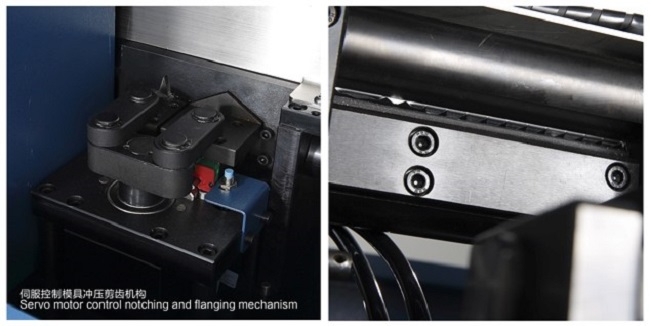

伺服控制模具冲压剪齿机构

采用伺服控制剪齿相对液压剪齿方式,具有机构体积小、速度更快、性能更稳定,无油污、运行噪音小的特点。

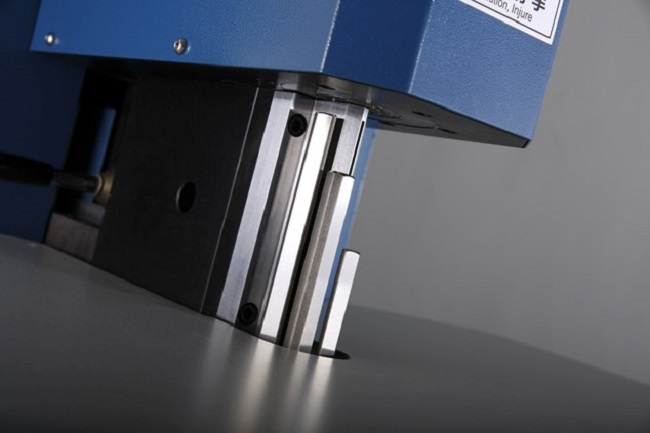

伸缩式双弯刀折弯机构

弯字机的核心在于弧度的成型效果,TPS-1800全自动弯字机采用伺服控制、高刚性齿轮传动,伸缩式双弯刀折弯、具有折弯力矩大、干涉区域小、表面无划伤等特点。

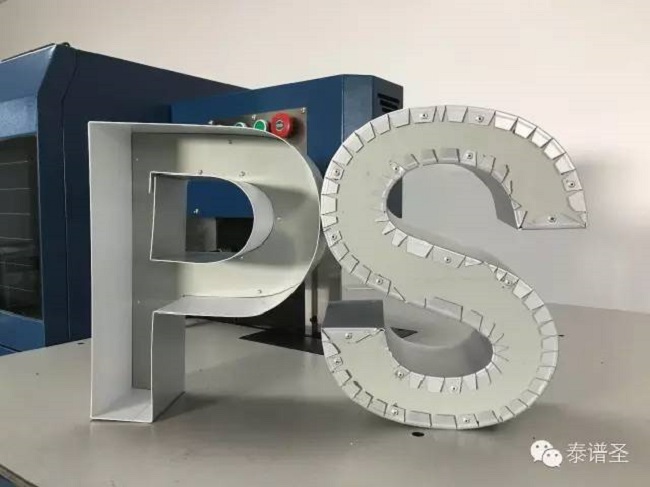

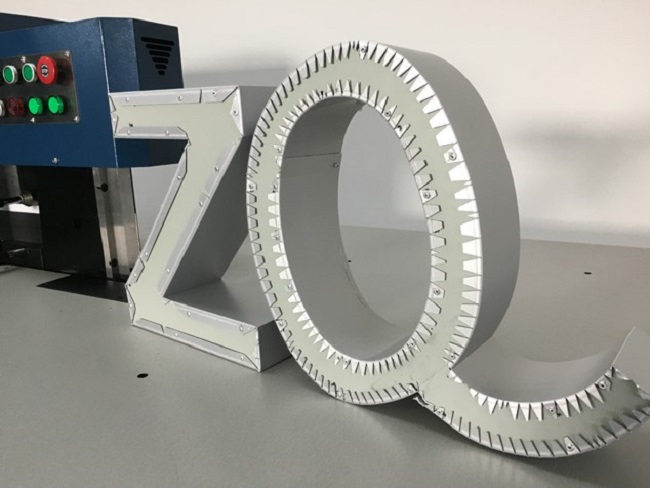

不锈钢材料加工

铝卷材料加工

S1800全自动剪齿弯字机软件支持

DXF/PLT文件输入,支持CAD、TYPE3、CRELDRAW、ILLUSTRATOR等。

S1800 全自动剪齿弯字机 主要技术参数

| 电源 | AC200V |

| 整机功率 | 4.0KW |

| 空气压缩 | 0.4—0.6MPa |

| 控制轴数量 | 5轴 |

| 小折U形 | R7mm |

| 小内外角距离 | 4.5mm |

| 开始折弯距离 | 3mm |

| 适用材料 | 不锈钢、镀锌板、铝卷(可以剪齿折边) |

| 材料规格 | 0.6-1.0mm |

| 加工高度 | 不锈钢(20-175mm)铝卷(50-175mm) |

| 送料方式 | 高精双丝杠交替式送料 |

| 剪齿方式 | 伺服控制模具冲压 |

| 剪齿角度 | 30°/120° |

| 折边方式 | 气动直角折边 |

| 折边宽度 | 14mm |

| 伺服电机 | 4PCs |

| 步进电机 | 1PC |

| 设备重量 | 800Kgs/900kgs |

| 外箱尺寸(L W H) | 2290×860×1560mm |